Comparison and Application of Galvanized and PPGI White Sheets

Galvanized sheet metal and PPGI (pre-painted galvanized steel) are two materials commonly used in modern industry and construction. While they both offer good corrosion protection, there are significant differences in application, performance and appearance. This article will provide a detailed comparison of these two materials to help readers better understand their characteristics and application scenarios.

First, the definition and characteristics of galvanized sheet

Galvanized sheet refers to a layer of zinc coated on the surface of the steel plate to improve its corrosion resistance. The galvanized layer forms a protective barrier that effectively prevents the steel from coming into direct contact with moisture and oxygen in the environment, thus extending its service life.

1. Corrosion resistance

The main advantage of galvanized sheet metal is its excellent anti-corrosion properties. The presence of a zinc layer effectively resists oxidation and slows down the rusting process. Galvanized sheets perform particularly well in wet or chemically corrosive environments.

2. Economy

The relatively low cost of galvanized sheet metal makes it an important and economical material for many industries. The relative simplicity of the fabrication process and the low cost of production make galvanized sheet widely used in construction and manufacturing.

3. Machinability

Galvanized sheet is easy to process and can be cut, shaped and welded to suit different production needs.

II. Definition and Characteristics of PPGI White Sheet

PPGI whiteboard is a material made by applying a layer of high-quality coating on the basis of galvanized sheet. This coating not only increases the aesthetics, but also further enhances the protective properties.

1. Aesthetics

PPGI whiteboards are available in a wide range of colors and a variety of finishes, such as glossy, matte or textured, to meet the needs of different design styles. Whether it is used for building facade or interior decoration, PPGI can add visual appeal to the space.

2. Excellent weather resistance

The coating of PPGI material has good weatherability and UV resistance, which makes it less likely to fade and age in outdoor environments. This feature ensures the aesthetic appeal and durability of PPGI in long-term use.

3. Processability

Like galvanized sheets, PPGI white sheets have good processing properties and can be cut, stamped and welded. However, due to the presence of the coating, PPGI needs to be more careful during certain processing to avoid damaging the coating.

III. Comparison of application areas

1. Application of galvanized sheet

Galvanized sheet is widely used in the construction industry, such as roofing, walls and fences. It is also commonly used in automobile manufacturing, appliance housings and other industrial products, and is favored for its economy and good anti-corrosion properties.

2. Application of PPGI whiteboard

PPGI whiteboard is especially suitable for exterior decoration and appliance shells because of its aesthetic and weather resistance. It is commonly used in the exterior facade of modern buildings, interior wall decoration and furniture manufacturing, and can meet consumers' demand for personalized design.

IV. Summary

Galvanized sheet and PPGI whiteboard have their own advantages and disadvantages, the choice of which material should be based on specific application scenarios and needs to decide. Galvanized sheet with its superior corrosion resistance and economy, in many traditional industries still occupy a dominant position. PPGI whiteboard, on the other hand, has become an indispensable material in modern construction and appliance manufacturing due to its aesthetics and versatility. In practical applications, understanding their characteristics will help to better select the right material for optimal use.

Featured articles and news

Focussing on the practical implementation of electrification.

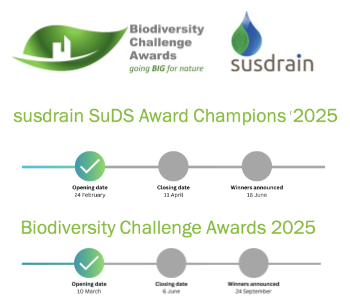

Sustainable Urban Drainage and Biodiversity

Awards for champions of these interconnected fields now open.

Microcosm of biodiversity in balconies and containers

Minor design adaptations for considerable biodiversity benefit.

CIOB student competitive construction challenge Ireland

Inspiring a new wave of Irish construction professionals.

Challenges of the net zero transition in Scotland

Skills shortage and ageing workforce hampering Scottish transition to net zero.

Private rental sector, living standards and fuel poverty

Report from the NRH in partnership with Impact on Urban Health.

.Cold chain condensing units market update

Tracking the evolution of commercial refrigeration unit markets.

Attending a conservation training course, personal account

The benefits of further learning for professsionals.

Restoring Alexander Pope's grotto

The only surviving part of his villa in Twickenham.

International Women's Day 8 March, 2025

Accelerating Action for For ALL Women and Girls: Rights. Equality. Empowerment.

Lack of construction careers advice threatens housing targets

CIOB warning on Government plans to accelerate housebuilding and development.

Shelter from the storm in Ukraine

Ukraine’s architects paving the path to recovery.

BSRIA market intelligence division key appointment

Lisa Wiltshire to lead rapidly growing Market Intelligence division.

A blueprint for construction’s sustainability efforts

Practical steps to achieve the United Nations Sustainable Development Goals.

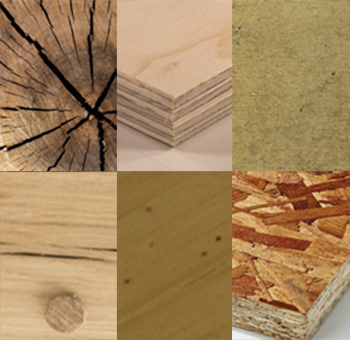

Timber in Construction Roadmap

Ambitious plans from the Government to increase the use of timber in construction.

ECA digital series unveils road to net-zero.

Retrofit and Decarbonisation framework N9 launched

Aligned with LHCPG social value strategy and the Gold Standard.